Inquiry :-

Dear Sir,

We are planning to qualify a welding procedure (as per EN ISO 15614-1:2017 + A1:2019) for double bevel butt welds on 30 mm thick S355J2 material, with the weld edges prepared by PUG cutting. Are there any metallurgical risks we should be aware of?

Reply:-

S355J2 is a non-alloy structural steel grade defined in EN 10025-2 (Hot Rolled Products of Structural Steels – Part 2: Technical Delivery Conditions for Non-Alloy Structural Steels), having Minimum yield strength as 355 MPa, J2 indicates, Impact tested at -20 °C with a minimum Charpy V-notch (CVN) energy of 27 Joules

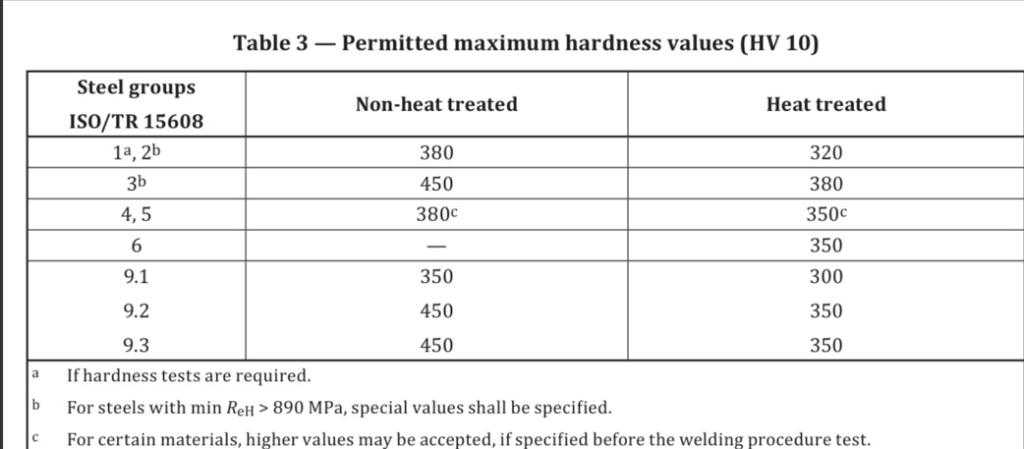

As per EN ISO 15614-1 WPQR, For EN 355 J2 material (Group no 1/1.2 as per ISO/TR 15608) as Weld condition hardness limit is max 380 HV (measured with HV 10) so practically, below 350HV is better. Pls. refer the Table No. 3 Permitted maximum hardness value provided in EN ISO 15614-1:2017 + A1:2019

A PUG cutting machine is a portable oxy-fuel (gas) profile cutting machine commonly used in fabrication shops and field welding work to prepare weld joint edges on steel plates and sections.

During thermal cutting, the heat-affected zone (HAZ) in S355J2 can undergo grain coarsening and, in some cases, martensitic transformation if cooling is rapid. These changes may lead to:

- Reduced impact toughness at low temperatures (especially at -20 °C).

- Elevated hardness in the HAZ, often exceeding 350 HV, increasing the risk of cracking.

In this regards, From Metallurgical point of view, I advice you that AFTER PUG cutting operation,

- Remove at least 2 mm from the cut edges by grinding to eliminate heat-affected material and surface oxides/slag.

- Ensure all edges are clean and free from contaminants before welding.

- Preheat between 75-100 °C before welding.

- AFTER edge grinding and BEFORE welding, check HAZ hardness using HV10.

- During welding maintain a maximum Interpass temperature of 200 °C.

- After welding, ensure hardness does not exceed 350 HV.

Following these steps will significantly improve your chances of passing the WPQR, particularly the impact test at -20 °C, while reducing the risk of HAZ cracking.

You did not mention your welding process, but If you are going for covered electrode practice, like SMAW (111) Process, use a low hydrogen electrode to minimise hydrogen-induced cracking risk.

Standard – EN ISO 2560-A covers coated electrodes for manual metal arc welding of non-alloy and fine grain steels.

I suggest, EN ISO 2560-A: E 42 4 B 32 H5 suitable for S355J2 because, 42 means, Minimum yield strength 420 MPa (matches S355J2’s requirement of 355 MPa yield, giving safety margin), 4 means, CVN 47 J at -40 degree Celsius (meeting against 47 J at -20 degree celsius), B stands for Basic-coated, low-hydrogen type (best for toughness and crack resistance) & 3 means Electro efficiency factor / Metal recovery and types of current AC/DC, 2 means, suitability for welding position (All position except, vertical down), H5 means, Diffusible hydrogen ≤ 5 ml/100g of weld metal (reduces hydrogen cracking risk)

If you are using Gas based Arc welding process, say GMAW (135) , EN ISO 14341-A (Welding consumables – Wire electrodes and weld deposits for gas shielded metal arc welding of non-alloy and fine grain steels).

Suggested consumable is G 42 4 M G3Si1, Here, G Means, Gas Shielding consumable Solid wire Arc welding process, 42 means, Minimum Yield strength 420 MPa, digit 4 stands for Impact toughness ≥ 47 J at -40 °C (Impact property of all weld-metal) , M for Mixed gas shield (e.g., Ar + CO₂) and G3Si1 is the Wire composition (Mn ~1.3-1.6 %, Si ~0.7-0.9 %). You could also use G 42 G 42 2 C/M G3Si1+Ti as per the availability.

One good advice, If you need good geometry and low HAZ for a qualified, critical weld — use mechanical bevelling / machining (milling, saw + machining). For routine plate work (medium thickness) plasma cutting is a good balance of speed and quality.

You can use a plasma torch with a PUG machine by adapting the torch holder, ensuring suitable speed control, and connecting a plasma power source — but it’s a mechanical retrofitting job, not just a drop-in replacement.

Hope this might help !

Follow-up : The inquirer has followed the advice and successfully passed the WPQR test !