Dear Sir,

We are preparing to qualify a TIG (141) welding procedure for a stainless-steel pipe as per EN ISO 15614-1, could you guide us on what is important to ensure a successful WPQR, especially for root pass integrity?

Reply:-

As a welding Educator and Trainer, I have been involved in witness & qualification of WPQR /WQR test of various materials conducted in accordance with AWS D1.1, D1.6, ASME IX, ISO 15614 part 1, 2 , ISO 9606 part 1, 2 etc.

Well, in addition to selection of suitable matching consumable -filler metals and shielding gas and process parameters, the most important aspect are maintenance of Heat Input (H.I.) as high H.I can slow down the cooling rate and increases the risk of chromium carbide precipitation at grain boundaries — a phenomenon called sensitization. Typically, takes place in the temperature range of 450°C to 850°C. Sensitized zones are prone to intergranular corrosion, especially in corrosive service environments. secondly, distortion and residual Stresses increase with increase H.I. Recommended heat input is usually in the range of 0.5 – 1.5 kJ/mm for TIG (GTAW) processes. In production joints, always see that WPS and code limits (e.g., EN ISO 15614-1 or ASME IX) is followed judiciously.

Preheat 25 °C (generally ambient temperature for Austenitic Stainless-steels ) and Interpass temperature max 150 °C, as Keeping inter pass temperature below 150°C helps avoid sensitization, causing a loss of corrosion resistance (particularly intergranular corrosion). secondly, preparing and cleaning of the weld joint using stainless-steel wire brush only to avoid carbon contamination and related metallurgical structural damage of the weld metal.

In addition to the above, It goes without saying that gas purging of the root is essential when depositing a TIG root pass. Argon (Ar) has been commonly used as purging gas.

Remember ! Root Purging is Non-Negotiable for TIG Welding

When performing a TIG root pass on stainless steels, oxygen contamination can result in oxidation, sugar (carbide precipitation), discoloration, or severe corrosion susceptibility. Therefore, internal purging becomes crucial to austenitic and Nickel alloys welds to protect the root surface.

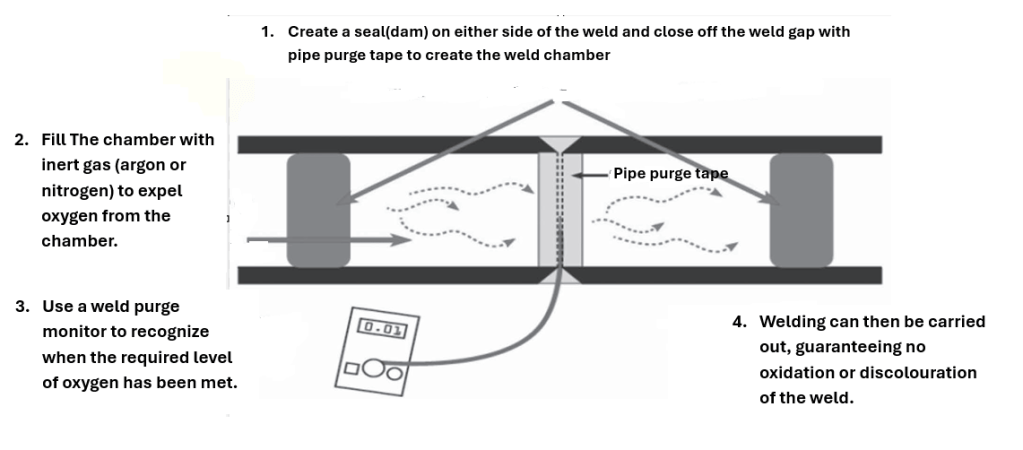

Here’s a recommended 4-step purging strategy to follow before welding with schematic:

- Create a Weld Chamber:

Use pipe purge tape to seal both sides of the joint and close off the weld gap. This forms a purge chamber around the root. - Inert Gas Backing:

Fill the chamber with an inert gas such as argon (preferred) or nitrogen to displace atmospheric oxygen. - Monitor Oxygen Levels:

Deploy a weld purge monitor to ensure the internal oxygen concentration drops below the desired threshold (typically <100 ppm for stainless steel). - Commence Welding:

Once the oxygen level is within the acceptable range, proceed with the TIG root pass to ensure a clean, oxide-free weld bead.

Source:- Andersen, L.; Andersen, T. E. Consulting Welding of Nickel & Nickel Alloys-Technical Update. https://www.huntingdonfusion.com/index.php/en/technical-support/white-papers-40017/3173-weld-purging-of-nickel-alloys