Inquirer:- Dear Sir,

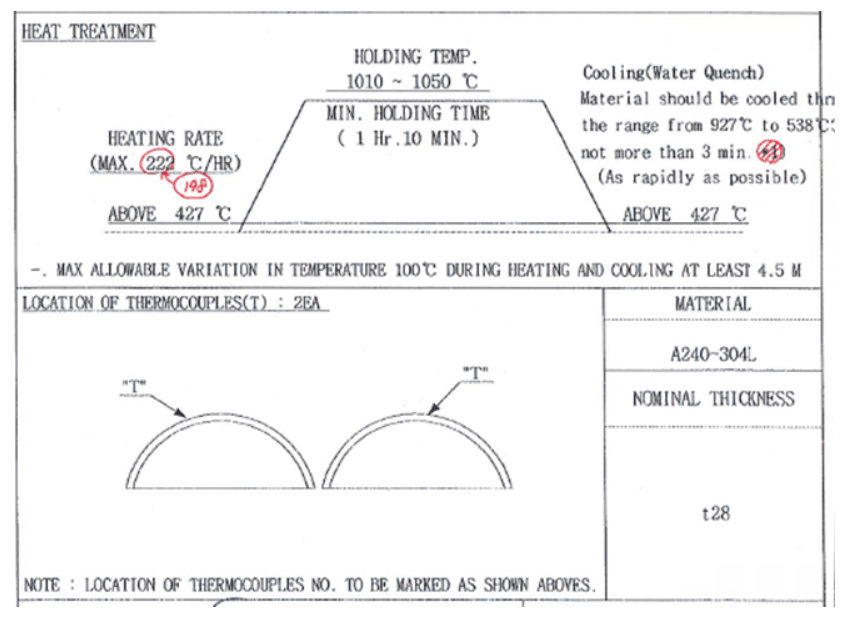

A heat treatment (HT) chart provided by our vendor for the SS304L components of a heat exchanger — specifically, the expansion bellow (26 mm) and channel cover dome (28 mm). The vendor has proposed a Heat treatment cycle as detailed in the chart, and we would like to clarify its necessity and appropriateness based on metallurgical principles and ASME standards.

We have also some questions based on above graph

- There is a Change in Girth Flange OD & Thickness, is there any Impact on HT cycle ?

- Expansion Bellow Thickness Increased from t26 mm to t28 mm — Any Change in HT?

- Applicable Standard for This Heat Treatment ? ASME Code reference ?

Reply:-

Dear Sir,

I reviewed the Heat treatment chart provided by your vendor, well before giving answers to your above questions, I would like to mention that although austenitic stainless steels (like 304L) are not typically hardened by heat treatment, solution annealing is performed to dissolve chromium carbides, restore corrosion resistance, and relieve residual stresses from cold forming or severe fabrication. So, above heat treatment chart has belonged to “Solution Annealing” Treatment to be given to stainless steel welded fabrications.

Now, regarding your above three questions,

Ans. 1: The girth flange (a ring welded around shell-dome or shell-nozzle joint for bolting or reinforcement) is not cold-formed and does not typically require solution annealing unless it experiences severe strain. Hence, it is not a heat-treated part in this context.

Ans. 2: Yes — holding time is influenced by thickness. Since the new bellow is 26 mm thick (vs 28 mm dome), same holding time is conservatively applied. No further adjustment needed if the time covers the thickest section.

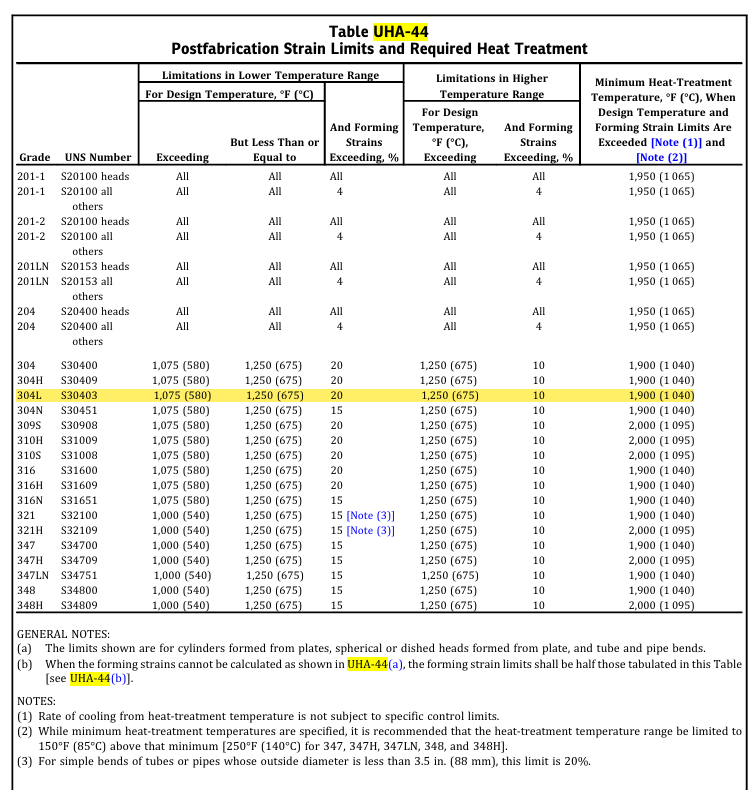

Ans. 3:- Per ASME Section VIII Div.1 (Ed. 2025), Table UHA-44, for 304L material with strains exceeding 10%, solution annealing is required at a minimum of 1040°C (1900°F). The vendor’s proposed cycle (1010–1050°C, 198°C/hr rate, and rapid water quench) is technically aligned with code and metallurgically sound.

As per my observations, the Heating Rate: Max allowable above 427°C is 222°C/hr. The selected 198°C/hr for 28 mm thickness is well within limits.

Cooling Rate: The water quench must bring temperature from 927°C to 538°C in under 3 minutes.

Thermocouple Placement: Minimum two thermocouples across 4.5 m to maintain temperature variation within ±100°C.

So, I recommend proceeding with the vendor’s proposed HT cycle. But I advised you to ask your HT Vendor to go for mock-up HT sample and testing prior to production HT.

Hope, this might be helpful to you.