Inquirer:-

Dear Sir,

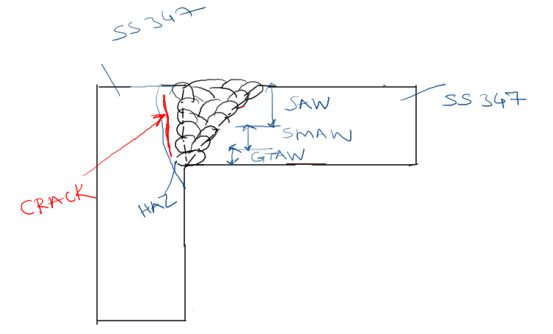

We have welded corner joint of SS Type 347 To SS Type 347 thick material with root run with GTAW ER347 , fill Run with SMAW E347 and ER 347 SAW Process. After, we have welded and did PWHT as per the code requirement, We have found a crack in HAZ. What could be the reasons behind it ?

(The weld joint design is reproduced for proper understanding of the issue! )

Dear Sir,

Looking at the failure of the Corner joint, I assume there can be multiple reasons under which, this kind of failure may happen:-

– Reheating Cracking/ Stress relaxation Cracking

–Liquation Cracking due to Nb & Mo in SS 347 composition

–Failure due to lamellar tearing

Reheating Cracking/ Stress relaxation Cracking is observed in Austenitic Stainless Steel especially in Type 347 Stainless Steel and it is found in HAZ and fusion zone of thick member.

Type 347 and 321 are stablized Stainless Steel due to the presence of Nb and Ti to reduce Inter granular corrosion attack. The mechanism for cracking in Type 347 is associated with the precipitation of NbC during the reheating cycle, as ASME Code requires that the thick structure should be stress relieved in the temperature range from 850 deg C – 900 deg C., before it can be put into service. intergranuar precipitation occur in the same temperature range as stress relaxation, locally high strains concentrate at grain boundaries and promote cracking. One interesting fact about this type of cracking is that it may be found in the Weld Metal also , besides only HAZ region.

Grain growth is the one of the causes for reheat cracking to occur, as grain growth increases the susceptibility to reheat cracking. Proper control over weld heat input to reduce the grain growth can reduce such problem. In your case, crack is observed to develop near HAZ/ FB of SAW process. High H.I used in SAW Process might have resulted in grain growth in this region and made a room for Reheat / stress relaxation cracking.

The second possibility seems to me is Liquation Cracking due to Nb and Mo in Type 347 SS composition, I see very least possibilities of Liquation Cracking in SS 347. If it had happened it can only become possible with NbC Consitutional cooling and in the presence of low melting point eutectics elements like S & P. However, the referred literature also does not suggest the role of ferrite content in weld metal to work as sink for low melting point eutectic but it is advisable to have FN between 5-11 is safe.

NbC constitutional cooling and segregation can be possible with SAW Process, because High H.I, Thick joint , grain coarsening and under high restraint after cooling of welds might lead to a liquation cracking.

The third possibilities, seems to me is failure due to lamellar tearing, which is a type of cracking that occurs inside the base metal, usually outside the HAZ of the weld, and generally run parallel to the fusion line of the weld. The rolled steel plate contains elongated inclusions oriented parallel to the surface of the plate and due to high concentrated stress experienced in corner joints due to cooling weld metal volume these inclusions can cause tear in the HAZ / Near Fusion boundaries and reduced the through -thickness ductility of the steel, resulting in a tear. This tear can enlarge and take the form of the crack.

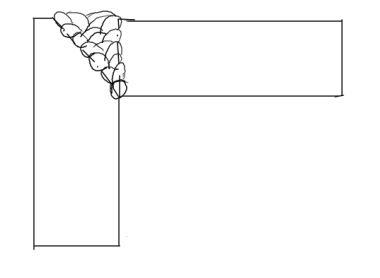

The risk of lamellar tearing will be greater if the stresses generated due to cooling of weld metal act in the through-thickness direction so, in my opinion, if the bevel angle can be changed in your corner joint as shown in the sketch below, the risk can be minimized because, due to change in weld orientation , the cooling stresses will not run in the through thickness direction and possibility to opening of the tear (if existed) will be reduced.

Suggested joint design for reducing the lamellar tearing problem.

The second suggestion is to apply butter layer on the surface of the joint using filler producing high ductility weld metal, because, 2 to 3 buttering layers of weld metal practically does not contain tear and also during cooling stresses these ductile weld metal layers can accommodate the stresses that’s why the possibility of lamellar tearing can be reduced.

Hoping that these suggestions might help !

References:-

- http://surl.li/fyife

- http://surl.li/fyifm

- http://surl.li/fyift

- Welding Metallurgy & Weldability- J.C.Lippod Willey Pub.