(Technical Data Sheet & Material Test Report supplied by the inquirer)

Dear Sir,

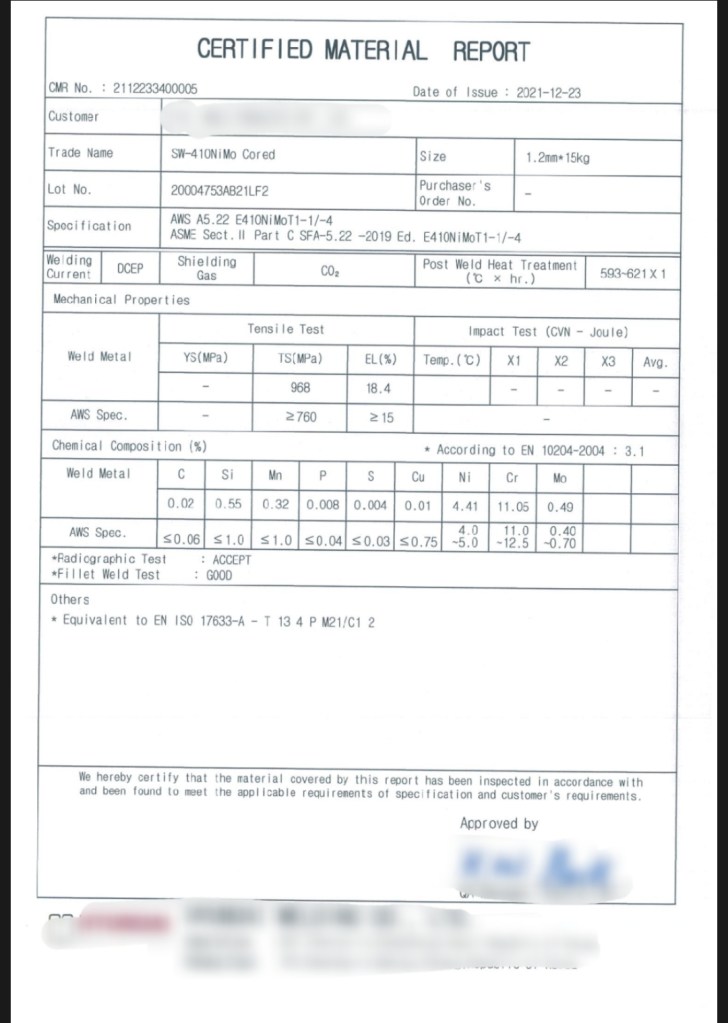

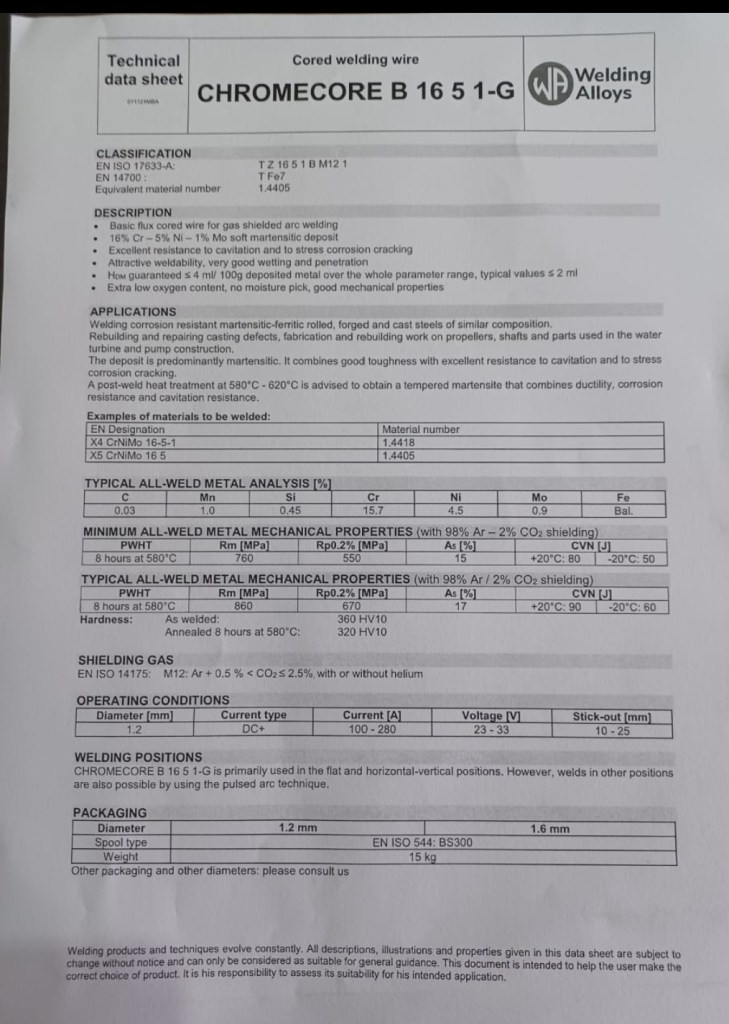

After having studied the product literature for consumable specification E410Ni Mo cored Wire classified under AWS A 5.22 classification & Material data sheet for consumable specification Chrome Core B 16 5 1 G classified under EN/ISO 17633-A.

-I have observed the following points:-

Difference in Cr % in deposited Weld Metal composition for E410Ni Mo cored Wire 11.05 % (which you routinely used and your procedure is qualified for the 410 Casting product) & your proposed Chrome Core B 16 5 1 G. is somewhat higher, 15.7 %.

Metallurgical point of view, Higher Cr % with filler metal is given to balance the effect of 4% wt. Nickel in filler metal. Because, 4-4.5 % Nickel in your consumable may reduce the temperature at which austenite is formed. So, When you PWHT ( To temper the as weld martensite), simultaneously, austenite will also be formed and during cooling this austenite will convert to “Fresh Martensite” which is hard. So, you may not meet hardness requirement in the weld joint.

Can you send me MTC of your base metal and qualified procedure ? because, The Cr% in your base metal & PWHT cycle is important. If they are within specified limit, there is no problem in using the proposed filler metal.

Rule of Thumb is No.1 You should be able to produce 100 % martensite in the as welded condition

Rule of Thumb is No. 2 is this 100 % as welded Martensite must be softened by tempering process (Tempered Martensite)

There is a solution also, You can go for double tempering process cycle to complete the conversion of martensite from austenite, which is time taking and expensive !

Do you have any hardness requirement after PWHT ? sometimes, NACE corrosion requirements suggest that your hardness should be 22 HRc after PWHT.

Second observation, regarding Mechanical Strength wise, the proposed consumable Chrome Core B 16 5 1 G is matching as per Min T.S 760 MPa. (In the TC after they have done PWHT of All-Weld Metal Test assembly) But your proposed consumable is recommending for F, H V position so for O position you may have to change the technique (Pulse Arc )

Hope this might help !