Inquirer:-

In railway bogie frame items (control arm support), we found a crack in-service condition after 2-3 yrs If we want to rework this material S355J2w+N by welding. Is it advisable or not? Please suggest!

Answer:-

Dear Sir,

I have referred to your query regarding the suitability of repair welding of S335 J2W+N steel railway bogie Frame items (control arm support).

I have found some useful information for you as follows

S335 J2W + N are weathering steel with low alloy content. Steels with a carbon content of less than 0.2 wt. % and alloying elements primarily Cu, Cr, Ni, P, Si, and Mn. These steel alloys have a chemical composition that allows for the formation of a rust/iron oxide layer to form early, providing a weather protective coat to the underlying steel. Weathering steels are covered under EN 10025 specifications. They are also known as CORE-TEN steels because they have a better combination of corrosion resistance and high tensile strength. CORE-TEN comes in two varieties: CORE-TEN A and CORE-TEN B. CORE-TEN A is designated by ASTM standard designation A 242, and CORE-TEN B is designated by ASTM standard designation A 588. Cor-Ten A and B alloys (US Co. brand) are comparable in general; however CORE-TEN A alloys have a higher phosphorus concentration for enhanced corrosion resistance. Depending on the thickness of the steel, GTAW, GMAW, SMAW, and SAW welding techniques can be used. Welding must be done in such a way that the rusting occurs in the same manner as the rest of the construction. [Ref. 1]

In terms of welding, ASTM A588 weathering steel is a structural steel that is covered by the AWS D1 Structural Welding Code. It is a category II steel that may be welded using prequalified welding processes (PWPS).

A standard repair procedure involves as

-Inspecting the component that failed for potential causes.

-Determining the suitability for repair by welding (Type of Material, Weldability, –Preheat/PWHT requirements Etc.)

-Understanding the service conditions and weldment requirements

-knowledge of construction code or standard

-Developing a repair welding procedure

a. Method for removing the defect (grind, machine, thermal, etc.)

b. Cavity contour (60°-90°). (The degree to which you grind.)

C. Intermediate Inspection Methodology (Visual, LPT, MP, UT etc.)

-Qualifying repair welding procedure specification

(If the weld was made with a prequalified WPS, I believe it would be allowed to repair it with the same WPS. D1.1, I believe the same WPS can be used as long as all of the original WPS essential variables requirements are met)

-Developing an inspection procedure & proper documentation.

The selection of filler metal for weld repair may be influenced by the following factors: –

-Specific construction code requirements

-Matching mechanical strength requirements

-Requirements for Rust Color Matching

The repair procedure is part of the weld procedure. You may need a single pass or multiple passes, For a single pass, standard electrodes such as E7018-1 and ER70S-6 may be used, to match the base metal (S355J2 W+N / CORE TEN B ) yield strength minimum 345 N/mm2 & Tensile Strength 485 N/mm2. Also with single-pass, much dilution can be expected from base metal to develop similar properties in weld metal for corrosion protection. However, Low H2 welding procedures and consumables are recommended.

Where, multi-pass is required to repair weld, It’s necessary to use a nickel-alloyed filler metal, containing up to 1% nickel will be used for welding weathering steels. AWS A5.28 ASME SFA 5.28 ER80S-Ni1 (GMAW) and AWS A5.29 ASME SFA 5.29 E81T1-Ni1C (FCAW) wires are two examples. Stick electrodes (SMAW) will be designated “C3,” indicating that they have been alloyed with 1% nickel

J.R Deepak et al [Ref. 2] have worked on welding of weathering steels. In their work, strips of wires were cut from the base metal to be used as a filler metal. They have aimed to achieve the matching mechanical and corrosion resistance property in weld metal close to the parent metal. They have successfully developed a weld joint using 100 % Argon shielding using GTAW.

The work by Byju John et al[ Ref.3 ] reports the Role Of Shielding Gas On Mechanical, Metallurgical &Corrosion Properties Of Corten Steel Welded Joints of Railway Coaches using GMAW. According to them, GMAW welded joint made using shielding gas (80% Ar – 20% CO2 ) has better Mechanical properties compared to the other two shielding gases (Pure CO2, 90% Ar – 10% CO2) taken for experiments and is comparable to that of Parent metal. Type of Shielding gas used has influence on the chemical composition and macro & microstructures, particularly acicular ferrite morphology yields very better mechanical properties.

I do not think that the availability of electrodes would be a problem; several companies have developed electrodes specifically for weathering steel welding. As with E8018-W for SMAW, these electrodes will have the “W” designation.

For flux shielded electrodes, you may try ESAB Brand MMAW OK 73.08, Gas-shielded MIG/MAG Welding OK Autorod 13.26 are the better choice.

In my opinion, it is preferred to use the electrodes designed for weathering steel to achieve the mechanical and corrosion properties close to the parent metal.

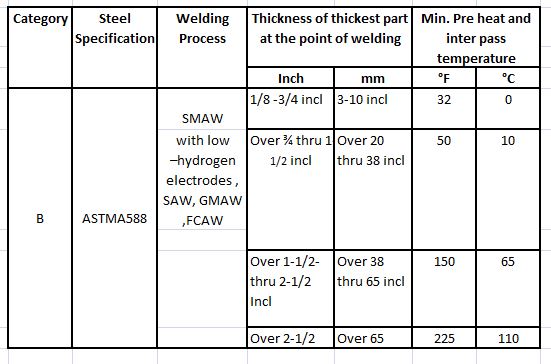

Preheat and interpass temperature requirements are based on the thickness of the base metal and follow those of Group II steels under AWS D1.1. The preheat requirements for A588 weathering steel, which is a Category B steel, are as follows:

Table 5.8

Prequalified Minimum Preheat and interpass Temperature

Reproduced table 5.8 for information from CLAUSE 5. PREQUALIFICATION OF WPS-AWS D1.1/D1.1M:2020

Your concern about fatigue performance of weld-repaired Control arm support (Railway boogie component) is technically very obvious. I am rather less aware of this kind of research on Fatigue performance of weathering steel welded joints in service so whether to repair it or not? , it is a matter of engineering judgment and wisdom!

In my opinion, if you select the right welding consumables and would follow, right weld repair procedure, I do not foresee any serious issues as per my knowledge.

References:-

https://www.azom.com/article.aspx?ArticleID=12974

Byju John et al, THE ROLE OF SHIELDING GAS ON MECHANICAL, METALLURGICAL AND CORROSION PROPERTIES OF CORT

J R Deepak et al, Experimental investigations of Corten A 588 Filler Rod for Welding Weathering Steel, Materials today proceedings 16(2019) 1233-1238

EN STEEL WELDED JOINTS OF RAILWAY COACHES USING GMAW, Adv. Sci. Technol. Res. J. 2016; 10(32):156–168.

AWS D1.1 Structural Steel Code