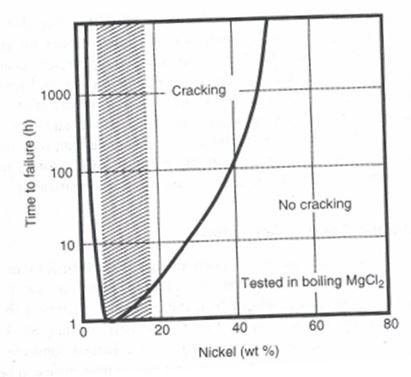

Many of the Austenitic SS are susceptible to SCC, mainly in Cl environment. Copson (1959) had reported- Effect of Nickel content on SCC in Austenitic SS in his published report in Physical Metallurgy of Stress Corrosion Fracture, Interscience, NY, pp.247-272. According to his findings, SCC can be avoided by selecting alloys with higher (>20%) such as Super austenitic SS or Ni-based alloys or Lower (<5%) nickel content-Ferritic or Duplex SS are the best choice. While 304 and 316 grade contains Ni in the range of 8 – 12 % Nickel, see Copson Curve. Fig 1 (Ref 1 )

Fig. 1 Copson curve for SCC in Stainless Steels, Shaded region represents nickel range of many austenitic Stainless Steels. Source (Ref:-1)

An interesting reference to the Effect of Ni on CSCC resistance – it is mentioned in the Lippold/Kotecki book (Ref.1), but the original work was published in 1959 by Copson. it was from a study of austenitic stainless steels, it shows worst SCC performance at 6% Ni or so, and improving performance as the Ni increases in austenitic Stainless Steels.

Ref 1:-:- J.C Lippod / D J Kotecki Welding Metallurgy of SS, Wiley Pub. Pg. 206-207