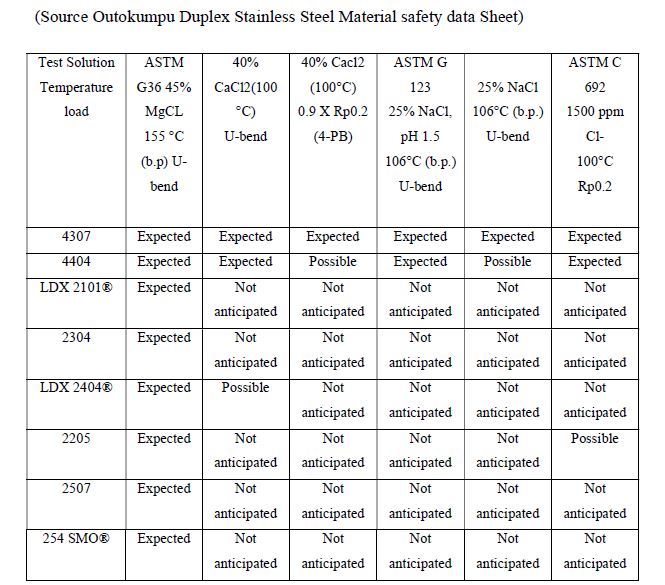

With reference to Outokumpu Duplex Stainless Steel Material safety data sheet. (Ref:-1-3) There are various test methods to rank stainless steel grades concerning their resistance to stress corrosion cracking. The results may show variation depending on the test program adopted & corrosion environment to which it is exposed to. A comparison is given of the SCC of commercially used austenitic stainless steels and duplex stainless steels by various accelerated laboratory corrosion test methods. The test specimens are immersed in different chloride solutions.

b.p. = boiling point. Expected = SCC is expected to occur. Not anticipated = SCC is not expected to occur. Possible = SCC may occur.

The noteworthy point is that duplex stainless steels are not resistant under very aggressive atmosphere, such as boiling concentrated magnesium chloride. However, they withstand stress corrosion cracking under many conditions where conventional austenitic grades are not able to perform.

Ref 1:- Outokumpu duplex stainless steel datasheet. (2013) Outokumpu Oyj, Helsinki. Stress Corrosion Cracking Properties of UNS S32101 – A new Duplex Stainless Steel with low Nickel Content, page 1–16, 2–2007, Outokumpu Oyj, Helsinki

Ref 2:-The welding consequences of replacing austenitic with duplex stainless steel, 1–2009, Outokumpu Oyj, Helsinki.

Ref 3:- Duplex stainless steels in the hydrometallurgical industry, pp 2-16,1-2010, and Corrosion testing of stainless steel for metal leaching applications, pp 7–18, 1–10, Outokumpu Oyj, Helsinki