The most serious cracking problem with nickel alloys is hot cracking in either the weld metal or close to the fusion line in the HAZ with the latter being the more frequent.

-The main culprit of this problem is sulphur but phosphorus, lead, bismuth and boron also contribute to the hot cracking problem.

-Stainless steel wire brushing followed by thorough degreasing with a suitable solvent is necessary before welding.

-Porosity can be a problem with the nickel alloys, the main culprit being nitrogen. As little as 0.025% nitrogen will form pores in the solidifying weld metal

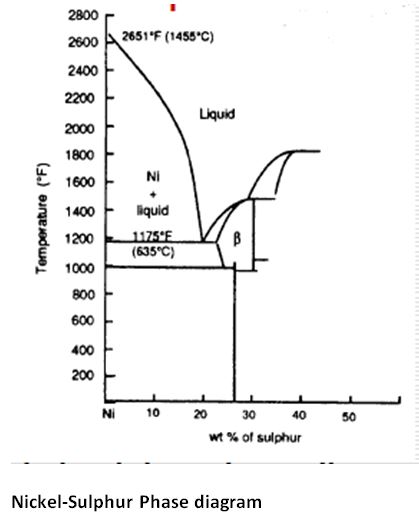

Nickel-sulphur phase diagram. Note the lack of solubility of sulphur in the solid nickel and the low melting point – 1175°F (635°C) of the eutectic. Major Problem with PH Ni-based alloys (Waspaloy® and Udimet® (Ni-Cr-Mo), Inconel 718, X-750, Custom Age 625 Plus® (Ni-Cr-Fe-Nb)Hot cracking in WM & HAZ)

Source:-

- J.F. Lancaster, in Metallurgy of Welding (Sixth Edition), 1999