Suppose we want to predict the FN of welded UNS S32205 Duplex Steel with Commercially available “matching” flux shielded electrode for duplex stainless – AWS A5.4/A5.4M E2209-XX (AWS A5.4/A5.4M, Specification for Stainless Steel Electrodes for Shielded Metal Arc Welding).

Let us assume 30% dilution (the 2205 base metal contributes total 30% of the union (15 % + 15 %) and the E2209-XX electrode the other 70%). The composition of the resultant weld metal can be predicted as below.

Step: 1 We should have a complete chemical composition of base metal (Mills / material suppliers Certificate / PMI Spectroscopy report)

Chemical Composition of UNS S32205 as per PMI Spectroscopy

| C | Si | Mn | P | S | Cr | Ni | Mo | Nb | Cu | Co | N |

| 0.023 | 0.37 | 1.50 | 0.018 | 0.001 | 22.37 | 5.72 | 3.21 | 0.11 | 0.14 | 0.08 | 0.177 |

Step 2

We should have filler/electrode chemical composition (As per ASME SEC IIC, Weld Pad Method/ Electrode manufacturer’s suppliers test report)

The Chemical compositions of the undiluted weld metal as per ASME SEC IIC weld pad test method

| Elements Nominal Values in (Wt%) | C | Mn | Si | S | P | Cr | Ni | Mo | Cu | N |

| Commercial E2209-16 | 0.031 | 1.08 | 0.59 | 0.007 | 0.025 | 22.38 | 9.15 | 3.35 | 0.096 | 0.18 |

Step 3

Calculate the Chromium equivalent and Nickel equivalent for base metal and filler/electrode composition:

Cr eq = Cr + Mo +0.7Cb

Ni eq = Ni + 35C+20N+0.25Cu

Step 4

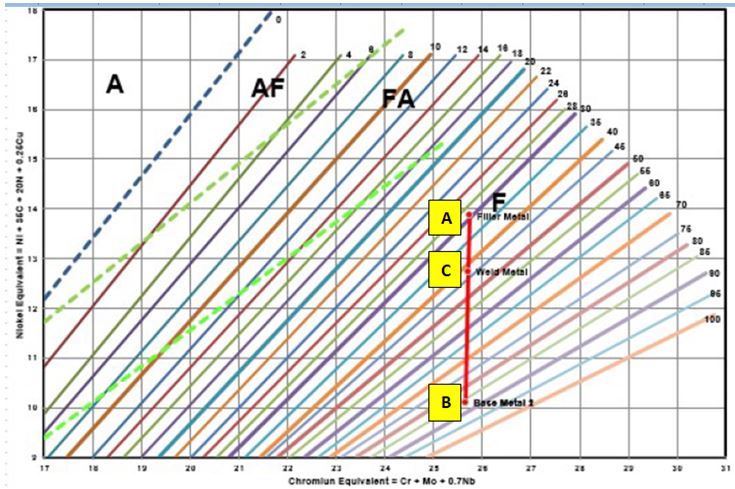

Plotting the values of Cr eq & Ni eq on the WRC-1992 diagram

The UNS S32205 composition is represented by point B (Cr equivalent 25.6%; Ni equivalent 10.1%) and the E2209-XX electrode composition by point A (Cr equivalent 25.7%; Ni equivalent 13.8%). As shown in Fig 1. At the same time Table 1. Lists the estimated composition of weld metal/synthetic base metal. Table 1 Calculates Weld metal composition / Synthetic base metal composition from given base metal and Filler/electrode composition, considering 30:70 dilution (Base metal: Filler Metal)

By Plotting the values of Creq & Nieq, it can be observed that any resultant weld metal from this mixture of A and B will be on the line that joins them. As we have assumed 30 per cent dilution, point C will give the resultant predicted FN = 42.7 approximately as shown in Fig 1. (See the calculated Weld metal composition point C is near thick orange line (FN=40) & between thin blue line (FN=46)

Fig. 1 FN 42.7 Prediction from WRC 1992 diagram for weld sample prepared by E2209 –XX electrode.